Micro Expanded Metal with Excellent Electrical Properties

Micro expanded metal is a type of special expanded metal with small openings, and it can be made from various alloys such as carbon steel, stainless steel, copper, aluminum, nickel, and titanium. It offers mulitple benefits including ventilation, light transmission, heat dissipation, high electrical conductivity, sound absorption, and filtration protection.

This material is widely used in medical equipment, lightning protection, batteries, renewable energy systems, and electromagnetic shielding applications. In shielding applications, micro expanded metal is especially critical – it effectively resists electromagnetic and radio frequency interference, as well as other forms of electromagnetic radiation, combining both physical and electrical properties to meet diverse shielding requirements.

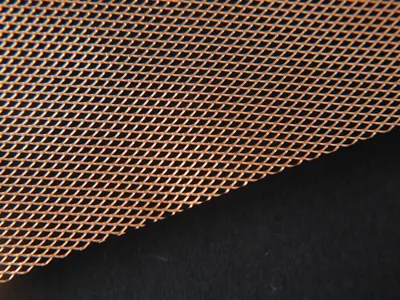

MEM-01: Copper micro expanded metal

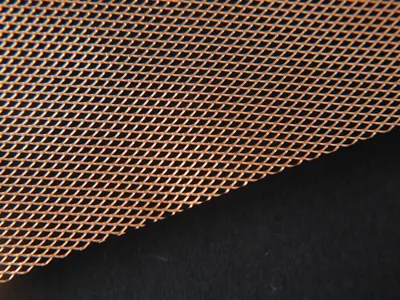

MEM-02: Stainless steel micro expanded metal

Specifications of micro expanded metal

- Materials: carbon steel, stainless steel, copper, aluminum, nickel, titanium and other alloys.

- Surface treatment: hot dip galvanized, PVC coating, powder coated.

- Surface type: raised, flattened.

- SWD: 0.005" to 0.118".

- LWD: 0.039" to 0.236".

- Strand width: 0.005" to 0.079".

Features of micro expanded metal

- Excellent Electromagnetic Shielding Performance

- Effectively blocks electromagnetic interference (EMI) and radio frequency interference (RFI), preventing equipment from external interference or causing interference to their surroundings, ideal for electronics, telecommunications and medical applications.

- Customizable aperture size allows for targeted shielding performance at specific frequencies.

- Lightweight yet High Strength

- The mesh structure provides light weight, making it ideal for weight reduction needs in aerospace and automotive industries.

- The expansion process enhances the metal's structural integrity, giving it high mechanical strength, as well as pressure and impact resistance.

- High Customizability and Flexibility

- Aperture size, hole pattern, and material can be customized to meet specific shielding, strength and weight requirements.

- Easy to cut, bend, and process, making it suitable for a wide range of engineering and manufacturing applications.

- Cost-Effectiveness

- The expansion process minimizes metal waste, leading to lower production costs.

- Long service life and low maintenance requirements reduce overall life-cycle costs.

Applications of micro expanded metal

- Electromagnetic Shielding and Radio Frequency Interference (EMI/RFI) Protection

- Electronic devices: Utilized for electromagnetic shielding to prevent devices from causing or being affected by external interference.

- Communication equipment: Provides RF shielding in base stations, satellite communications, and radio systems to ensure stable communication quality.

- Medical equipment: Applied in high-precision instruments such as MRI and X-ray machines to prevent electromagnetic interference and protect electronic components.

- Environmental Protection and Filtration

- Water filtration: Used in drinking water or industrial wastewater treatment to effectively trap impurities and protect water treatment systems.

- Air filtration: Serves as a component in air purifiers and industrial exhaust filtration systems to remove harmful substances and improve air quality.

- CO2 Electrolysis

- Electrode support: Offers high conductivity, corrosion resistance, and a large specific surface area, thereby enhancing electrolysis efficiency.

- Enhanced catalytic activity: Functions synergistically with catalysts to optimize electrolyte distribution and accelerate reaction rates.

- Catalyst fixation: The mesh structure provides a stable surface for catalyst attachment, thereby improving catalytic performance.

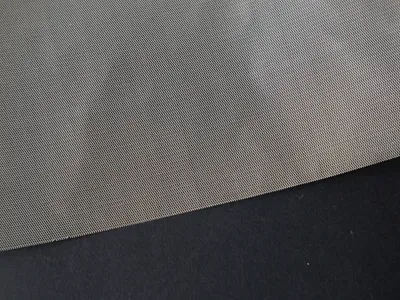

MEM-03: Screening micro expanded metal.

MEM-04: Ceiling micro expanded metal.

MEM-05: Covering micro expanded metal.

MEM-06: Filter micro expanded metal.