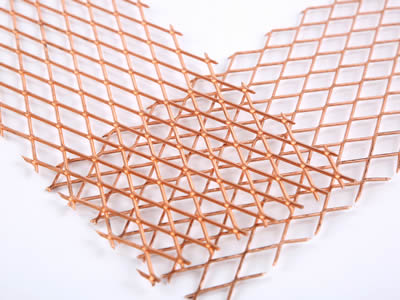

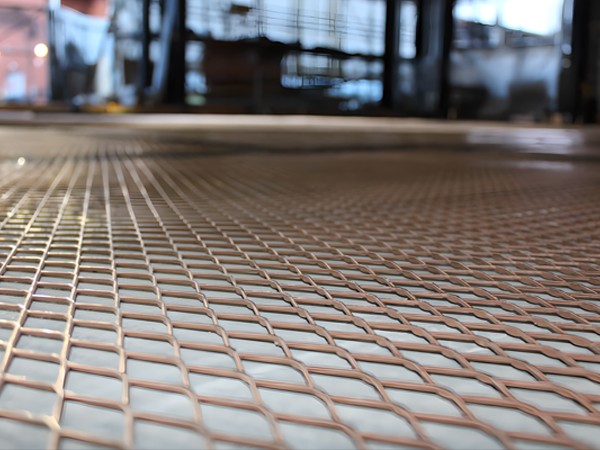

Flattened mesh

Copper expanded metal sheet is formed by stretching and stamping, because of this particular processing method, the material in the production process is essentially lossless. Copper expanded metal is electrically conductive so that it can be applied to projects that require conduction, such as electrical grounding, EMI shielding room, high voltage test laboratory and other uses. Copper expanded metal with good corrosion resistance, but if exposed to the outside, the surface will produce a layer of patina. And this layer of patina can become a protective barrier of copper expanded metal. The patina may shows many different colors, of which brown is the most common. The special appearance of copper expanded metal makes it also can be used in the design industry or decoration projects.

Different mesh types of copper expanded metal sheet

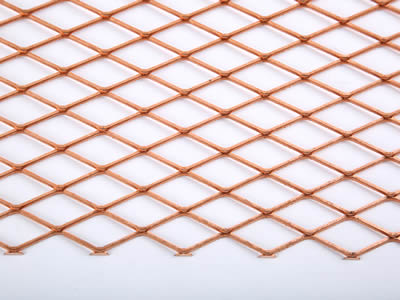

The most typical varieties of expanded copper mesh types include flattened mesh and standard mesh.

Flattened mesh

Standard mesh

Different angle images of copper expanded metal sheet

CEM-01

CEM-02

CEM-03

CEM-04

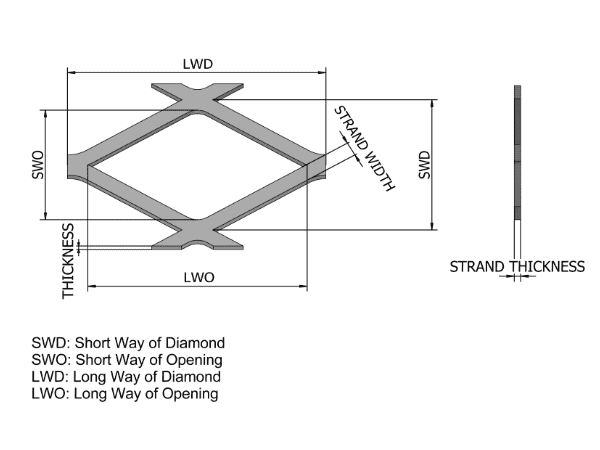

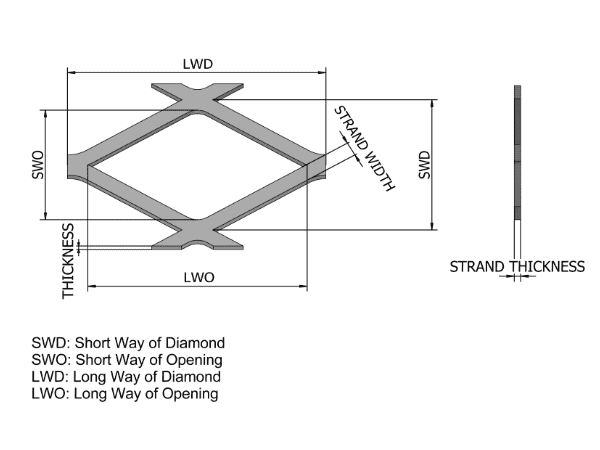

Specifications of copper expanded metal sheet

| Item | SWD (mm) | LWD (mm) | Thickness (mm) | Strand Width (mm) |

|---|---|---|---|---|

| CEMS-01 | 2.3 | 4 | 0.4 | 0.3 |

| CEMS-02 | 2.5 | 5 | 0.5 | 0.5 |

| CEMS-03 | 3 | 6 | 0.6 | 0.7 |

| CEMS-04 | 3.5 | 4 | 0.5 | 0.5 |

| CEMS-05 | 4 | 8 | 0.5 | 0.5 |

| CEMS-06 | 4.5 | 5 | 0.5 | 0.5 |

| CEMS-07 | 5 | 10 | 0.6 | 0.6 |

| CEMS-08 | 7 | 12 | 0.8 | 0.7 |

| CEMS-09 | 7 | 8 | 0.6 | 0.6 |

| CEMS-10 | 8 | 16 | 0.8 | 1.2 |

| CEMS-11 | 10 | 20 | 1.2 | 1.5 |

| CEMS-12 | 12 | 25 | 1.2 | 1.2 |

| CEMS-13 | 20 | 30 | 1.0 | 2.0 |

| CEMS-14 | 25 | 50 | 2.0 | 2.5 |

| CEMS-15 | 30 | 60 | 3.0 | 3.0 |

| CEMS-16 | 40 | 80 | 4.0 | 6.0 |

| CEMS-17 | 50 | 100 | 5.0 | 6.0 |

Raised copper expanded metal

Flattened copper expanded metal

Inspection of copper expanded metal sheet

Copper expanded metal sheets need to be tested and qualified by the inspection department before packaging.

Raw material test

LWD size measurement

SWD size measurement

Strand width measurement

Thickness measurement

Whole mesh size measurement

Packaging of copper expanded metal sheet

Packaging should be firm and safe. The copper expanded metal sheets are packed in carton that are wrapped with air bubble film on the outside to prevent damage. The carton with air bubble film is then sealed with black protective film around it to prevent water and moisture. And a wooden box is used for external packaging. Finally, plywood is installed around the pallet to ensure that the copper expanded metal sheets will not be squeezed. The bottom part is made of square steel pipe welded into a bracket and bundled with steel straps into a flat package. It can also be based on the client's requirements.

Top 1: Copper expanded metal sheets in the center of the carton

Top 2: Air bubble film wrapped copper expanded metal sheets carton

Top 3: Black protective film sealed copper expanded metal sheets carton

Top 4: Finally, wooden cases are used for steel grating package.

Shipping of copper expanded metal sheet

Avoid impact, extrusion, rain, moisture, and chemical corrosion during transportation.

Storage of copper expanded metal sheet

The expanded copper metal sheet should be stored in a warehouse with air circulation, relative humidity of less than 85%, and no corrosive gases. If the product is placed in the ground floor warehouse, it should be more than 200 mm from the ground.

Features of copper expanded metal sheet

Applications of copper expanded metal sheet

Copper expanded metal sheet is widely used in many industries, such as:

It also can be used as many things, such as:

Copper expanded metal sheet for grounding system

Copper expanded mesh for high voltage laboratory

Copper Expanded Metal Ceiling

Copper expanded metal decoration

Copper expanded metal facade