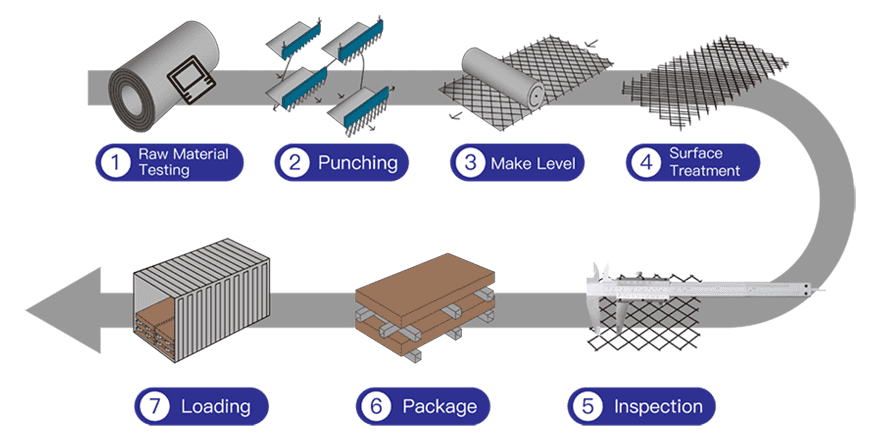

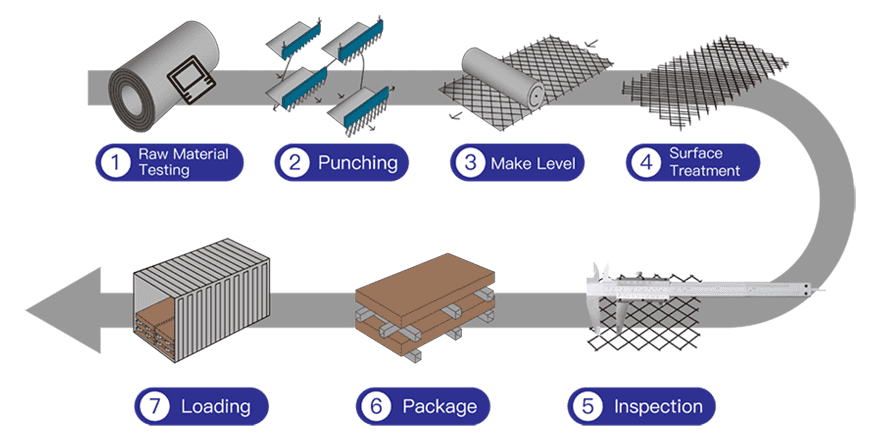

Expanded metal mesh production process

Expanded metal mesh is made of galvanized steel plates, aluminum, stainless steel and other ductile metal sheets after special mechanical technology treatment and expansion. It not only used for building reinforcement, but also often used in building decoration. It becomes a good choice among an increasing number of designers due to its low price, lightweight, rich 3D visual effect, overall transparency and flexibility.

Features

Raw Material Testing → Punching → Make Level → Surface Treatment → Inspection → Package → Loading

Expanded metal mesh production process

Surface Treatment

We offer a wide range of finishing options which can be applied to our expanded metal mesh product range, for both decorative and protective purposes.

Our finishing solutions are suitable for metal mesh products used across a range of applications, including building cladding, internal and external architectural features.

Galvanizing

Hot dip galvanizing is a common solution which provides an effective layer of protection to mild steel. The process involves dipping our expanded steel mesh in to a bath of molten zinc and causing a chemical reaction between the zinc and the metal surface to form a uniform, dense zinc layer. This zinc layer can effectively prevent the steel material from rusting and extend its service life.

Powder Coating

Powder coating is a commonly used surface treatment method for expanded metal mesh. It uses electrostatic spraying to form a coating on the surface of the expanded metal mesh after heating and curing. This method offers excellent durability and an aesthetically pleasing color finish to the expanded metal mesh.

PVDF Coating

PVDF coating is a kind of electrostatic spraying, and it is also a way of liquid spraying.

Expanded metal mesh after PVDF coating can effectively prevent fading and staining, and have excellent resistance to ultraviolet radiation and cracking.