Something About the Differences Between PVDF Coating and Powder Coating

Powder coating and fluorocarbon (PVDF) coating are common surface treatments that provide high quality surface coatings for a variety of materials to improve their appearance, durability and corrosion resistance. Here we will introduce the advantages of the two surface treatments in different applications.

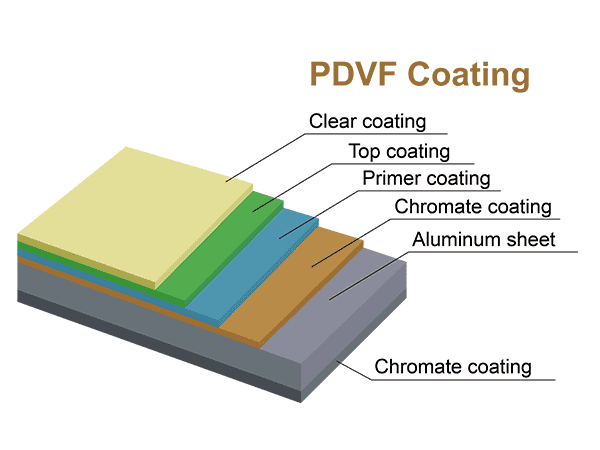

Fluorocarbon (PVDF) coating is a resin based liquid coating system. They are widely used when the exterior of a project requires a durable coating to resist weathering, chalking, fading, and UV rays while offering exceptional protection for the substrate. They also possess a self-cleaning and excellent stain resistance properties, thus requires little and even no maintenance. Due to their exceptional resistance to chalking and chemicals, they are often used in harsh and critical environments such as coastal areas, chemical plants and hospitals.

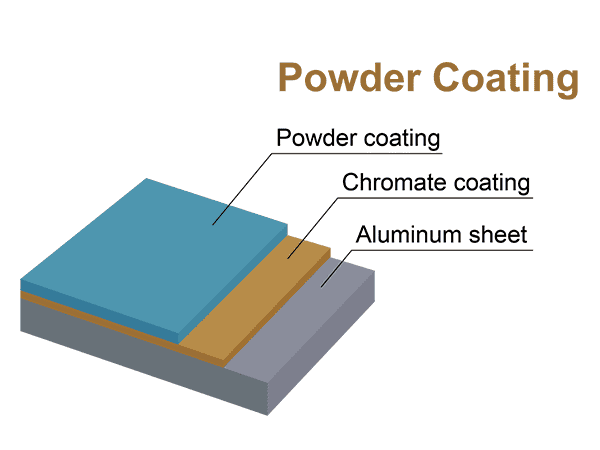

Powder coating is a dry finishing process where a color or coating is applied by electrostatic spraying. The coated part is then placed in an oven where the powder melts into a uniform, solid coating across the entire surface of the part. It can provide both functional and decorative surface coatings in a wide range of colors, finishes, and textures that are not easily achieved by conventional liquid coating methods. In architecture, they are widely used as the coating of windows and door frames, fencing and building facades.

Differences Between The Two Coating Methods

PVDF Coating VS Powder Coating

|

PVDF |

Powder coated |

| Wear Resistance |

Excellence |

Good |

| Shelf Life |

10–15 years |

7–8 years |

| Price |

Expensive |

Economic |

| Coating Thickness |

30–35 μm |

50–60 μm |

| Process |

Air spraying, thermal spraying, high pressure spraying |

Electrostatic spraying |

| Color Options |

RAL color chart or customize |

| Coating Brand |

Akzo or domestic |

Working Principle of These Processes

- Air spraying. It uses a spray gun to spray the paint products from the nozzle, and then the negative pressure generated by the compressed air at the nozzle of the air compressor will convert the paint flow into particles and then shoot it towards the surface to be processed.

- High pressure spraying. It takes advantage of the principle of pressure to carry out the construction, and often in the construction process, the high pressure spraying mode will completely control the paint mist dispersed all around, and concentrate it to the core position of the whole construction process. This method significantly improves the quality of fluorocarbon paints, and exhibits a refined result.

- Thermal spraying. The main advantage of this spraying mode is environmentally friendly. Before construction, you need to preheat the coating products, do a good job in preparations and then control the temperature well, to present a good spraying effect.

- Electrostatic spraying. It utilizes the electrostatic principle to allow the paint to be evenly sprayed on the surface of the object to be sprayed. Specifically, the object to be sprayed is grounded while the spraying device is connected to a negative high voltage through a power source. This creates a high voltage electrostatic field. In this field, the paint is charged and further atomized. Because of the principle that like charges repel and opposite charges attract, the charged paint is attracted to the surface of the object to be coated and forms a uniform, firmly adhered thin film there.